BGS Drilling solution

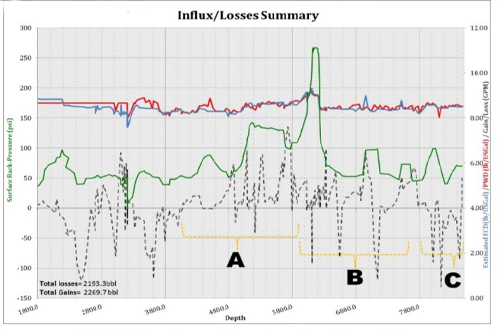

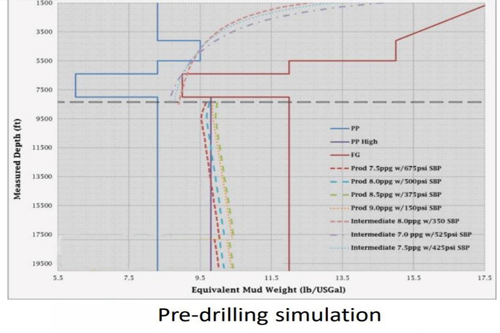

Integrated state-of-the-art Technology, Management Expertise, Safety, and the highest level of Quality and Service, BGS strives to advance current drilling practices. MPD is an evolving technology that can solve a wide range of problems, including differential sticking, unstable formations, wellbore ballooning, lost circulation, and loss-kick situations.

The goal is to reduce total well expenditure through mitigation of Non-Productive Time (NPT), safety enhancement, innovative products, and skillful application of unconventional drilling techniques

MPD is the process whereby the wellbore pressure exerted by the drilling fluid is controlled using surface backpressure arising from the pipe being sealed at the surface by a rotating head and a choke manifold. This enables uninterrupted drilling through narrow pore-fracture pressure windows. Pressure control is maintained using a combination of fluid density, circulating friction, and surface pressure adjustments.

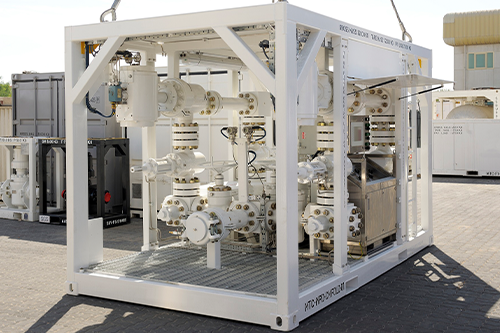

BGS Technology … Built-for-Purpose

- compact footprint & high mobility

- Trailer-Mounted or Skid-Mounted

- Withstands extreme climate & annular pressure conditions

- 87% Reduction in footprint from the original MPD manifold, and 65% reduction in footprint from the current MPD market standard

- Built to NACE MR-0175/API 16A Standards with full traceability

- Electric System Allows the choke to function reliably in very hot / cold conditions, without the cost of running and maintaining hydraulic lines

- Trailer Mounted Choke Skid, cuts down on mobilization costs & delays

- Industry Leading Powerful finite Intelli-choke (electric drive) that produces extremely precise pressure control and quick response times eliminates the need for back pressure pump or rig pump diverter systems

- Dual Redundant Chokes with Gut Line Bypass

- Rig Floor Remote HMI that has been designed for limited driller interaction to control the choke system

How can service differentiate technology?

Always guarantee the “A” team

BGS ES Highly specialized MPD trained personnel onsite are provided to help train the rig crew and guide the unconventional drilling process

Support & training leverage

Engineering service lets clients to help maximize results from their operation.

Post-well reviews and reports

Help optimize long running projects well-overwell, creating value from past experiences.